2023 VIOLI Drawing bench VMTRI253S

2023 VIOLI Drawing bench VMTRI253S

Description

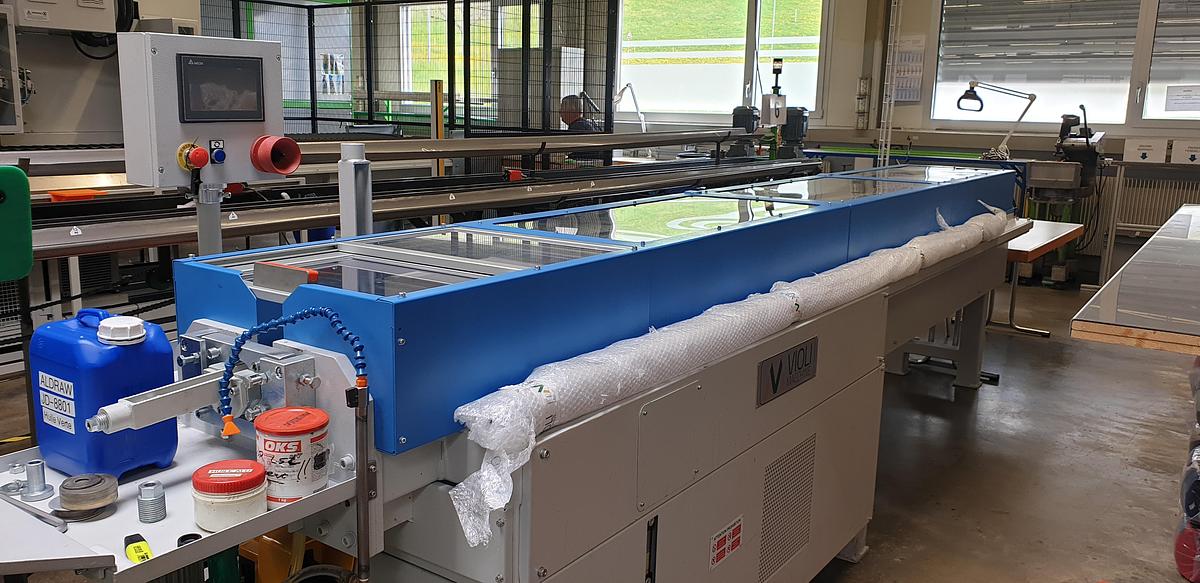

VIOLI Drawing Bench VM/TRI25-3s

Manufactured in 2023

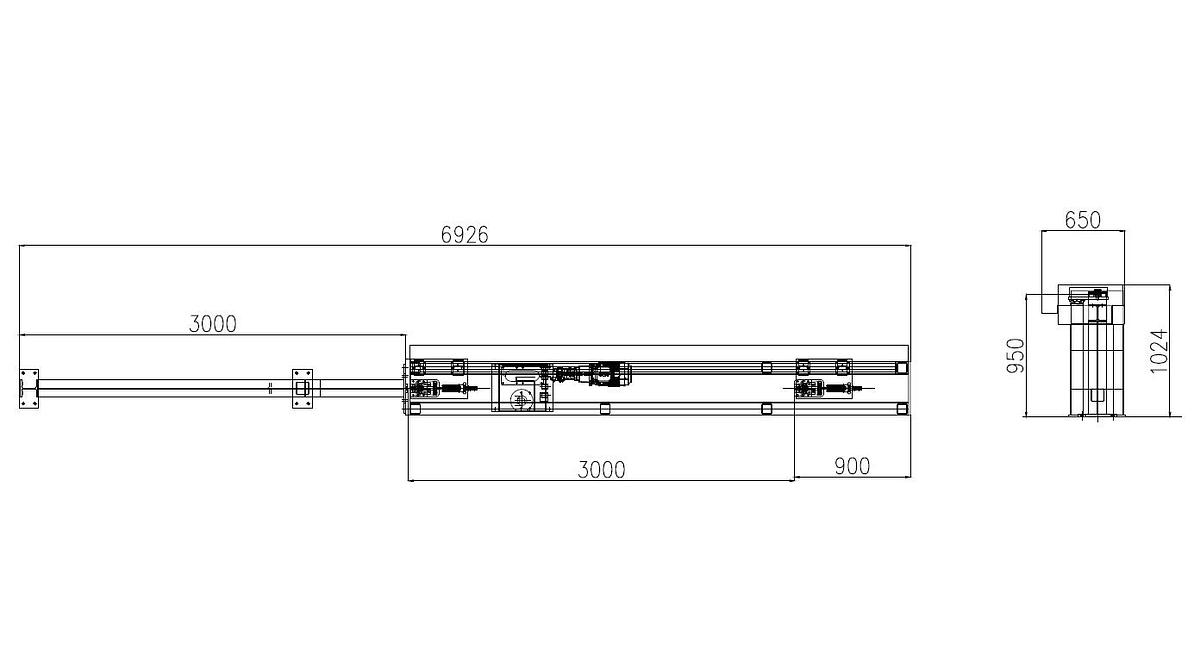

The VIOLI Drawing Bench VM/TRI25-3s is a robust and innovative machine designed for precise and efficient metal drawing, featuring a 3-meter useful length and a powerful 2,500 kg pulling capacity. Its patented hydraulic system ensures linear pulling, compact design, and consistent quality.

TECHNICAL SPECIFICATIONS

Useful Length: 3 Meters

Pulling Power: 2,500 kg

Drawing force: Max. daN 2500

Operating hydraulic pressure: 180 bar

Drawing speed: Min. 0 m/min. - Max. 17 m/min.

Drawing reduction: Around 15% of the section

Clamping force POINTER: 100 Ton

Tolerance: 1 mm

Power supply: 400 V - 50 Hz

Electric power: 9,2 KW

Hydraulic oil: ISO 46

Motor Power: 9.2 kW - 380 V, 50 Hz

Noise: At the workplace LP < 70 dB(A)

Hydraulic System: Proportional hydraulic pump

Carriage Sliding: with ball circulation guides

Construction and movable installation of a hale holder to house 1 O hales in line with the trolley;

Predisposition for cooling the lubricating oil with the insertion of a stainless steel pipe coil in the tank;

Adjustable Die holder;

Bar support system;

Tank with pump for lubrication;

Opening/ closure of pliers operated manually by pneumatic pistan;

Compliance: Machine comply with the UE conformity regulations.

DETAILED FEATURES

Operating System: The system uses a hydraulic piston and patented technology for optimizing space, ensuring linearity with the drawing hole, and minimizing bending of the supporting structure. It allows for a compact die length and double the useful pulling stroke.

Caliper Return: A patented double-circuit chain technology returns the caliper to its starting point. This allows the hydraulic piston's length to be half of the useful working stroke.

Pulling Power: The pulling power is in line with the drawing die.

Speed Control: Manual adjustable speed from 0 to 16 meters per minute (0−16 Mt/m). It offers fine regulation of the speed and constant speed derived from the hydraulics.

Tolerance: The tolerance is 1 mm.

Hydraulic System: Features a proportional hydraulic pump.

Motor Power: 9.2 kW - 380 V, 50 Hz.

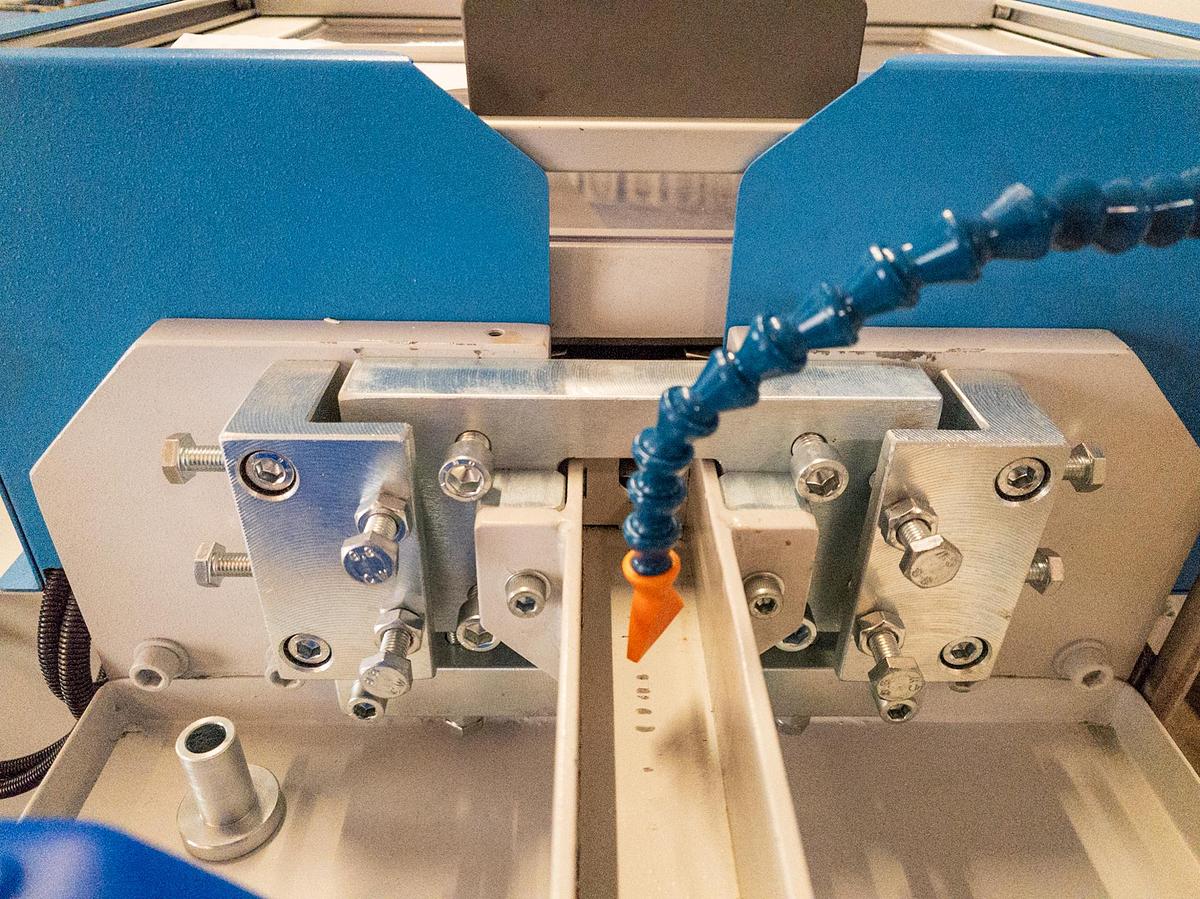

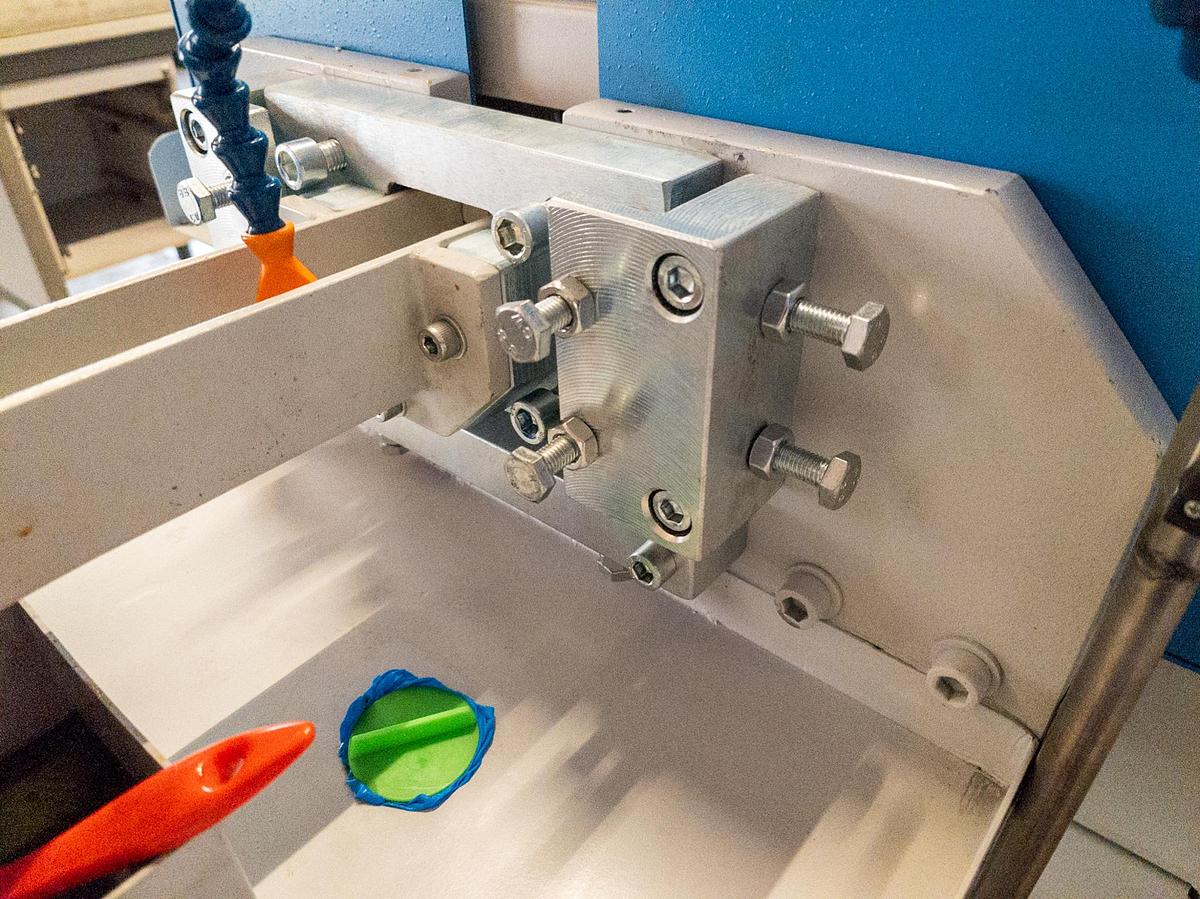

Carriage: Carriage sliding with ball circulation guides.

Hole Holder: Construction and movable installation of a hole holder to house 10 holes in line with the trolley.

Lubrication: Includes a lubrication tank with a lubrication pump. There is also a predisposition for cooling the lubricating oil with a stainless steel pipe coil in the tank.

Die Holder: Adjustable.

Bar Support: Includes a bar support system.

Pliers Operation: Opening and closure of pliers are operated manually by a pneumatic piston.

Control Panel: The machine is equipped with a control panel

FUNCTION

The hydraulic drawing bench VM/TRI253S is a machine used for the cold reduction of the cross section of a metallic rod, both with round or shaped profile, or of an empty or “animated” metallic tube. The reduction of the section is obtained by passing the product through a calibrated drawing die and pulling it, using a mechanical clamp with the force required to obtain the reduction of the section.

COMPOSITION OF THE DRAWING BENCH

The machine is composed of the following main components:

- Metal structure

- Carriage equipped with a hydraulically controlled clamp

- Carriage drive unit

- Hydraulic system

- Electrical system

Metal structure

The metal structure is composed of a recirculating ball guide.

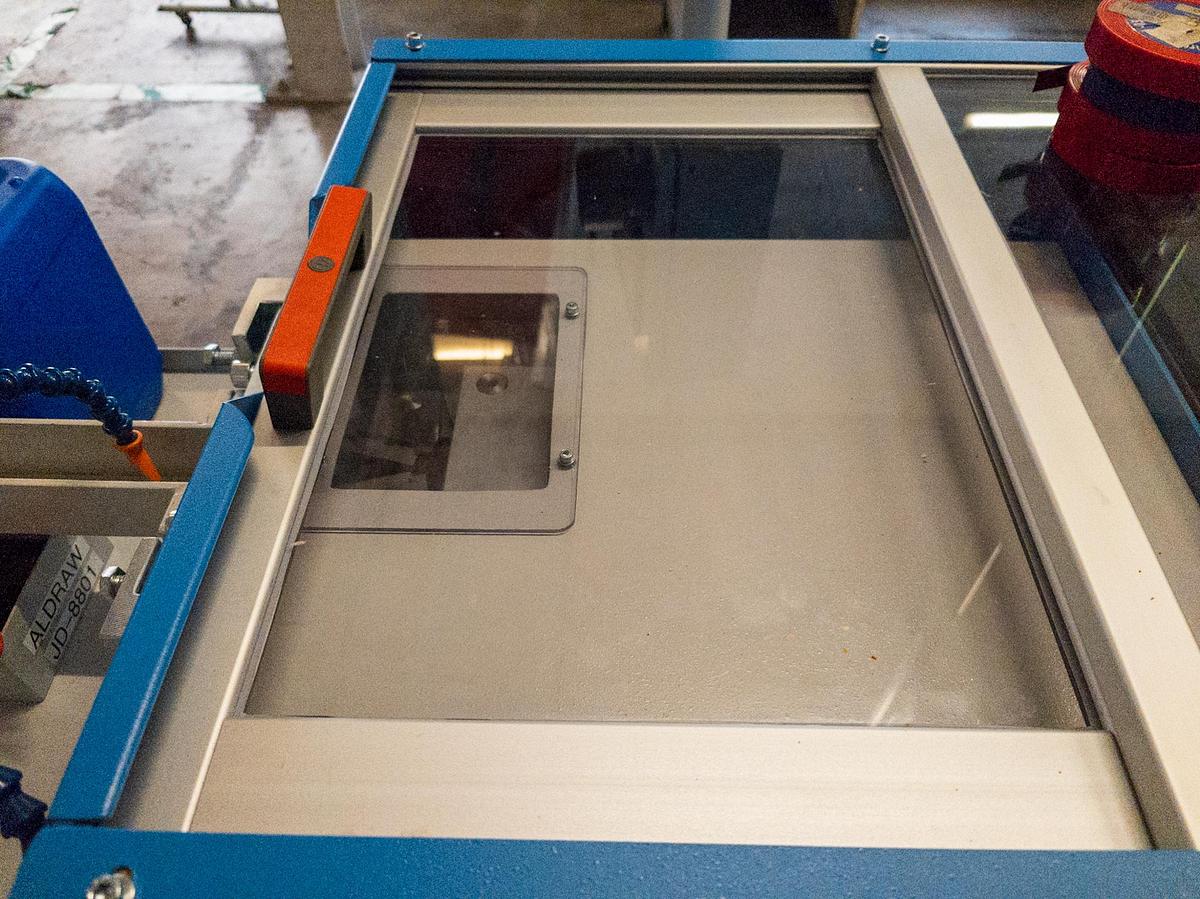

At the end of the rails, a suitable sized plate supports the drawing die. Particular protections composed of bend plates connected to the structure delimitate the clamp motion area and prevent the processed rod from being thrown out in case of breakage during the drawing process.

Equipped carriage

A special carriage equipped with a clamp pulling the rod slides on the recirculating ball guide. On the carriage is mounted a special clamp with pneumatic opening/closing system, composed of inclined planes and expansion wedge.

A particular clamp, which increases the closing force when the working force grows, pulls the rod.

Carriage drive unit

The carriage drive unit is composed of a double-acting hydraulic cylinder and by a ring-opened special chain. One end of the chain is firmly fixed to the metal structure (fixed end), whereas the other one is fixed to the hydraulic clamp control cylinder.

Hydraulic system

The hydraulic system consists of a pump and a group of valves and solenoid valves that allow the movements of the drawing cylinder.

A pneumatic group allows the movements of the opening/ closing of the clamp.

Electrical system

The electrical system has been designed and manufactured in compliance with the EN 60204-1 standard. A general switch located on the outside of the control panel is used to energize the machine.

On the front part of the machine is installed the control panel that contains the switches, buttons and warning lights for monitoring and managing the machine.

A foot pedal allows to manage the rod pointing process and the advancement of the drawing cylinder.

Specifications

| Manufacturer | VIOLI |

| Model | Drawing bench VMTRI253S |

| Year | 2023 |

| Condition | Used |

| Stock Number | 4041 |

| Useful Length | 3 Meters |

| Pulling Power | 2,500 kg |

| Drawing force | Max. daN 2500 |

| Operating hydraulic pressure | 180 bar |

| Drawing speed | Min. 0 m/min. - Max. 17 m/min. |

| Drawing reduction | Around 15% of the section |

| Clamping force POINTER | 100 Ton |

| Tolerance | 1 mm |

| Power supply | 400 V - 50 Hz |

| Electric power | 9,2 KW |

| Hydraulic oil | ISO 46 |

| Motor Power | 9.2 kW - 380 V, 50 Hz |

| Noise | At the workplace LP < 70 dB(A) |