Menu

Relocation & overhaul of a 1500×3 cut-to-length line

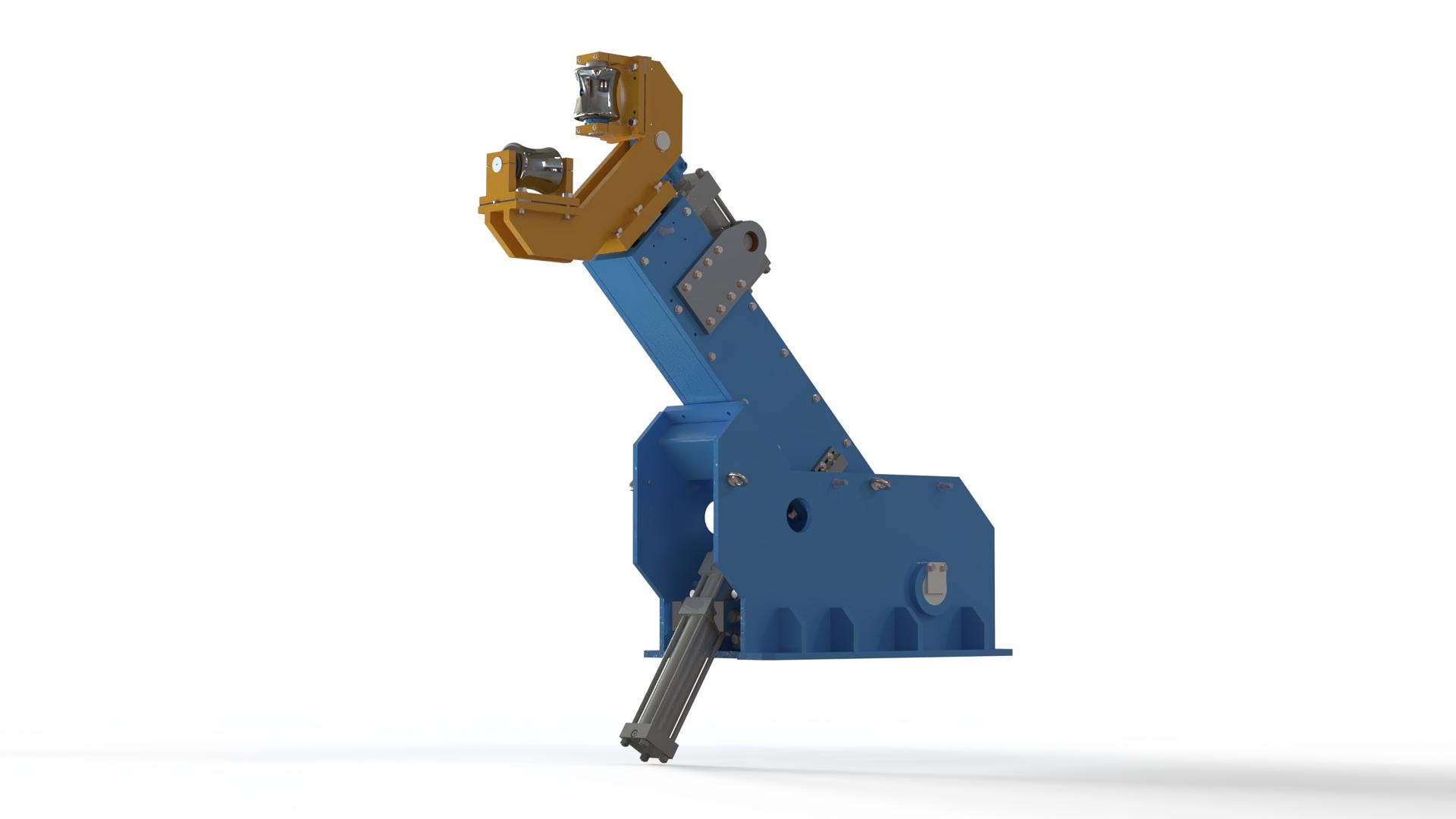

EUROMAQUINA carried out the relocation, overhaul and commissioning of a CTL 1500×3 line, managing the project on a turnkey basis, from initial engineering through to final optimization.

① 📋 Preparation & engineering

Every project starts with detailed planning. We analyzed the existing technical documentation, carried out preliminary measurements, and defined the optimal layout for the line.

- Analysis of technical documentation

- Preliminary measurements and layout definition

- Validation of safety requirements with the teams

- Logistics and resource planning

- Engineering and custom manufacturing of the uncoiler mandrel support

During this phase, the engineering and custom fabrication of the recommended modifications are developed.

In this case, we designed a new uncoiler mandrel support, adapted to the new line configuration.

In parallel, safety requirements and project logistics were validated with our team.

② 🛠️ Controlled disassembly

Each component is identified and protected. Disassembly is carried out following clear and traceable procedures:

- Marking and palletizing of cables

- Identification of hydraulic and pneumatic circuits

- Mechanical, electrical, and hydraulic disassembly

- Selective re-engineering of non-reusable components

③ 🚚 Loading, transport & unloading

Complete management of the industrial relocation. EUROMAQUINA handled all loading, transport, and unloading operations, ensuring the integrity of the equipment.

- Safe loading

- Transport

- Controlled unloading at destination

④ ⚙️ Complete reassembly on site

Once on site, the team executed the full reassembly of the line with meticulous technical precision:

Mechanical installation

- Positioning, alignment, and anchoring

- Adjustments and checks

Electrical installation

- Cabinets and operator desks

- Wiring, connections, and adjustments

- Electrical and programming tests

Hydraulic and pneumatic installation

- Positioning of units

- Connections and functional testing

All connections were validated through electrical, electronic, and programming tests.

⑤ ✅ Commissioning

With the line assembled, the commissioning and production validation phase began:

- Line adjustments and internal tests

- No-load trials

- Production tests

- Acceptance tests

⑥ 🚀 Performance optimization

The line is ready for production. The project concluded with a performance optimization phase, during which key line parameters were adjusted to maximize:

- Speed,

- Stability,

- Process quality,

- Operator training.

The result is a fully operational, stable installation aligned with the customer’s production objectives.

This project reflects EUROMAQUINA’s way of working: rigorous planning, applied engineering, and technical support through to final production.

If you are considering the relocation, modernization, or commissioning of an industrial line, contact our team and let’s define the best technical solution together.

At EUROMAQUINA, we support you from engineering through to production start-up.

📧 Email: commercial@euromaquina.com

📞 Phone: +34 916 58 72 60

📱 Whatsapp: +34 669 360 542