Menú

Nueva enderezadora de barras de cobre de hasta Ø70mm fabricada por Euromáquina

ESPECIFICACIONES TÉCNICAS

Rango de diámetro de enderezamiento: de Ø15 a Ø70 mm

Longitud de barra: de 3 a 6 metros

Características del material: Cobre y aleaciones

Límite elástico: de 250 a 450 N/mm²

¿QUE INCLUYE?

· Mesa de carga

· Sistema de alimentación de barras y canal de entrada

· Pinch-roll de alimentación en entrada con rodillos hiperbólicos

· Enderezadora de 2 rodillos WRPF 50/70

· Pinch-roll de salida

· Canal de salida

· Sección de salida y cuna de recogida

· Sistema de control eléctrico

· Seguridad

· Software Datastraight completo (configuración automática de la máquina)

MÁS DETALLES DE LA ENDEREZADORA DE BARRAS DE COBRE DE HASTA Ø70mm FABRICADA POR EUROMÁQUINA

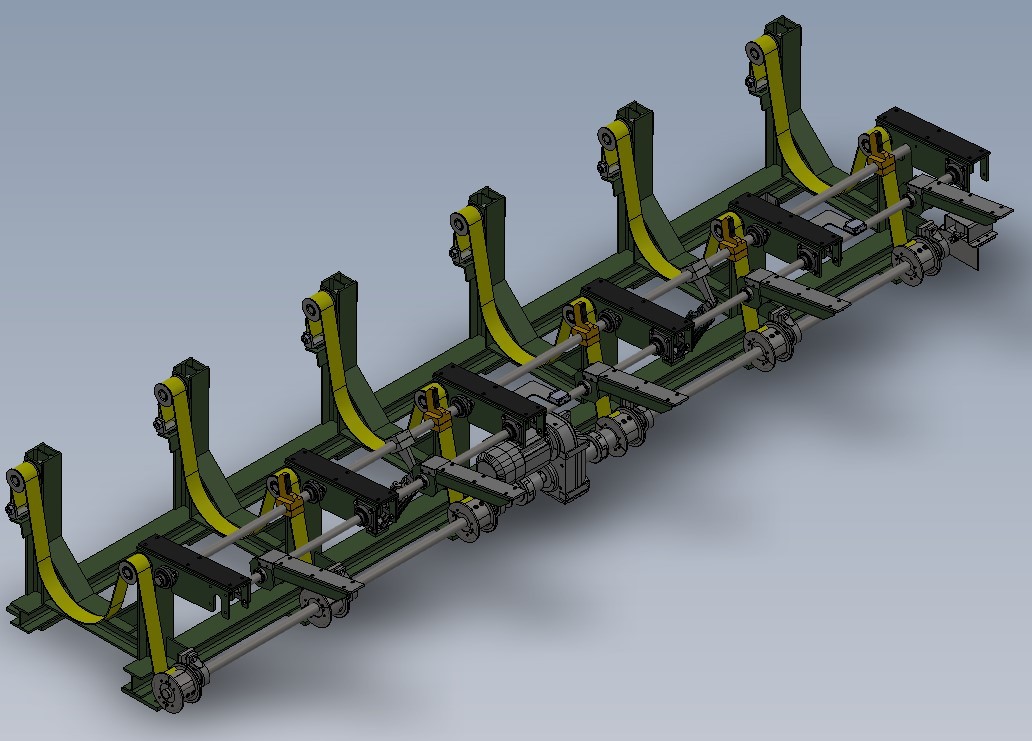

1. MESA DE CARGA

· Cargador de haces con eslingas sin fin (eslingas sin fin motorizadas)

· Área de transporte de cinta horizontal (5 módulos)

· Estructura vertical con ajuste manual de la parte superior para el ajuste de diámetro.

· Piezas de contacto protegidas antinarcas

2. SISTEMA DE ALIMENTACIÓN DE BARRAS Y CANAL DE ENTRADA

· 7m de longitud

· Regulación centralizada del sistema de recogida de barras

· Protección interna de plástico

· Apertura/cierre neumático

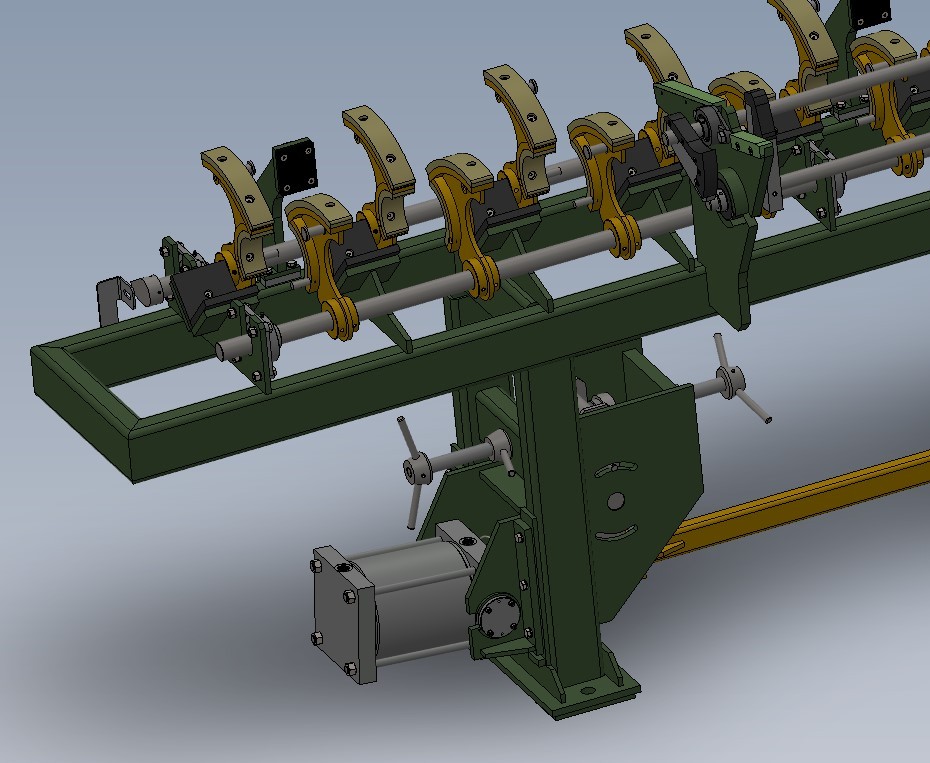

3. PINCH-ROLL DE ALIMENTACIÓN CON RODILLOS HIPERBÓLICOS

· Rodillo inferior motorizado

· Rodillo superior con cilindro neumático, altura ajustable

· Diseño hiperbólico

· Velocidad variable adaptada a la velocidad de la línea

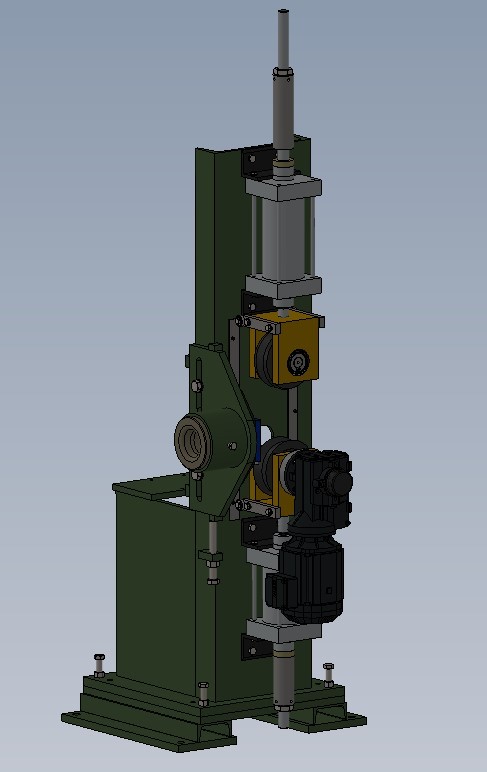

4. ENDEREZADORA DE 2 RODILLOS WRPF50/70

· Rango de diámetro adaptado de 25-70 mm

· Rodillos de enderezado con perfil rectificado para optimizar el enderezado

· Puerta frontal con contactos de seguridad

· Guía de entrada de nylon, tamaño adaptado al rango 25-70 mm

· 1 juego completo de placas guía laterales

5. DATASTRAIGHT COMPLETO (Configuración automática de la máquina)

4 ajustes de control numérico con encoder absoluto:

· Altura del rodillo superior

· Ángulo del rodillo superior

· Ángulo del rodillo inferior

· Guía de centrado lateral

Software completo con las siguientes pantallas principales de interfaz:

· Base de datos para la configuración automática de la máquina

· Valores de producción reales

· Mantenimiento y reajustes

· Alarmas

6. PINCH-ROLL DE SALIDA

· Rodillo inferior motorizado

· Rodillo superior con cilindro neumático, altura ajustable

· Rodillos con diseño en V

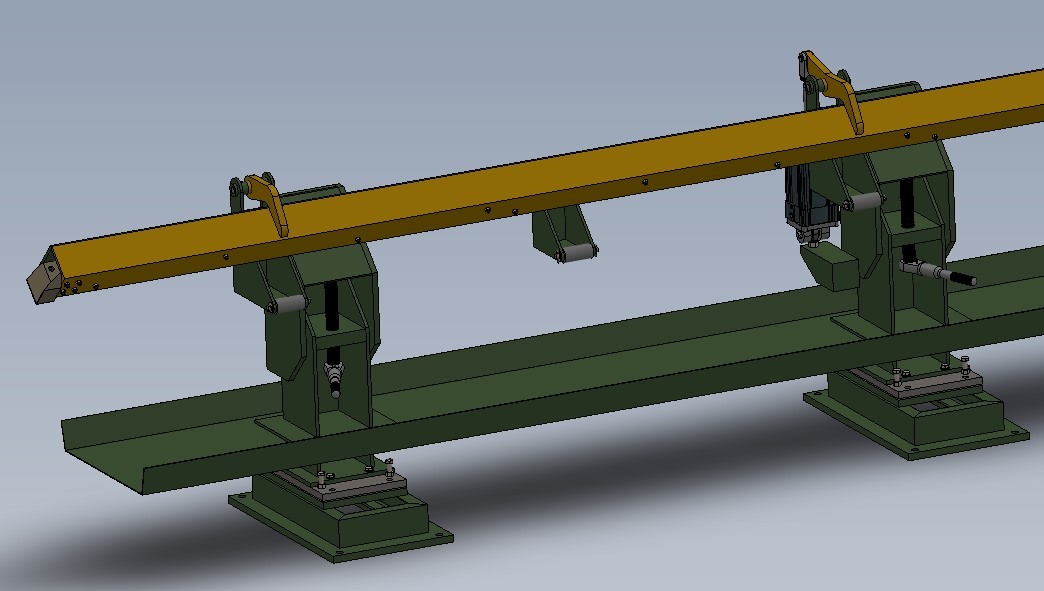

7. CANAL DE SALIDA

· 7m de longitud

· Protección interna de plástico

· Apertura/cierre neumático

· Forma romboidal

· Contacto que no deja marcas

· Descarga a un lado

· Ajuste vertical para adaptarse a la flexión de la barra

8. SECCIÓN DE SALIDA Y CUNA DE RECOGIDA

· Sección inclinada con tope de longitud (control de rectitud)

· Cuna de salida con eslingas sin fin motorizadas

9. SISTEMA DE CONTROL ELÉCTRICO

· Potencia y control de la línea completa

· Interfaz HMI del operador para los controles

10. SEGURIDAD

· NUEVAS puertas de seguridad de la máquina

· NUEVAS barreras fotoeléctricas perimetrales, barreras y vallas según normas CE